In today’s competitive U.S. kitchen and cabinetry industry, edge banding and grain direction are key factors influencing not only aesthetics but also overall shop drawing accuracy and installation success. This comprehensive deep dive explores why they matter, how they intersect in CAD drafting, and best practices for avoiding costly mistakes in residential shop drawings. We’ll […]

Introduction In the world of residential kitchen design, precision isn’t a luxury—it’s a necessity. Joinery and material callouts are not just technical details; they’re the backbone of functional, durable, and aesthetically pleasing kitchens. For architects, designers, and contractors across the USA, understanding and specifying these elements correctly during drafting prevents installation errors, cutdowns on costly […]

In the precision-driven world of architectural millwork, joinery accuracy is the cornerstone of quality craftsmanship. From casework to wall paneling, accurate joinery details ensure not just structural integrity but also ease of assembly, reduced waste, and elevated aesthetic appeal. In recent years, software advancements like Microvellum have revolutionized the drafting and production processes. This article […]

In the fast-evolving world of millwork design and production, shop drawings are more than just technical documents. They are the bridge between concept and construction, ensuring accuracy, efficiency, and compliance in every custom-built solution. For U.S. millwork contractors, understanding the distinctions between commercial and residential shop drawings is critical. Each sector carries unique design expectations, […]

How CNC-Ready Shop Drawings Reduce Waste in U.S. Millwork Operations In today’s competitive U.S. millwork industry, reducing material waste is more than a cost-saving measure—it’s a strategic imperative. With increased demand for sustainability and lean manufacturing, CNC-ready shop drawings have emerged as an essential solution to minimize waste while increasing precision and efficiency. This article […]

In the fast-paced world of custom cabinetry manufacturing, accuracy is not just a metric—it’s a mandate. For U.S. woodworking professionals, every miscalculation or drafting error can translate into costly material waste, production delays, or dissatisfied clients. In this context, Cabinet Vision has emerged as a vital software tool that enables unparalleled precision in cabinetry design […]

Introduction: The Cost of Inaccuracy in Casework Projects In the world of architectural casework, precision is non-negotiable. Errors in shop drawings lead to rework, change orders, missed deadlines, and significant budget overruns. According to data from McKinsey, construction rework can consume up to 30% of project time and 5%–10% of the overall cost. The root […]

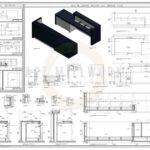

The world of custom cabinetry has evolved significantly, with modern technology transforming the design and production processes. AutoCAD 3D modeling has emerged as a crucial tool for cabinetmakers, millwork professionals, and contractors who seek precision, efficiency, and streamlined workflows. By integrating CAD-to-CNC processes, designers can transition seamlessly from digital blueprints to high-quality custom cabinets, minimizing […]

The millwork industry in the United States is on the cusp of a significant transformation. As technology evolves, consumer preferences shift, and sustainability becomes a priority, millwork professionals are reimagining the way they design, produce, and deliver custom woodwork. With 2025 fast approaching, millwork companies, contractors, and designers must stay ahead of the curve to […]

The integration of 3D modeling using SolidWorks has been a game changer for the custom millwork industry. As clients demand more complex and unique woodworking solutions, millwork professionals in the USA have adopted 3D modeling technology to provide accurate, detailed, and efficient designs. SolidWorks, a powerful software widely used in mechanical engineering, has found a […]